mobiTOUCH – Benefits

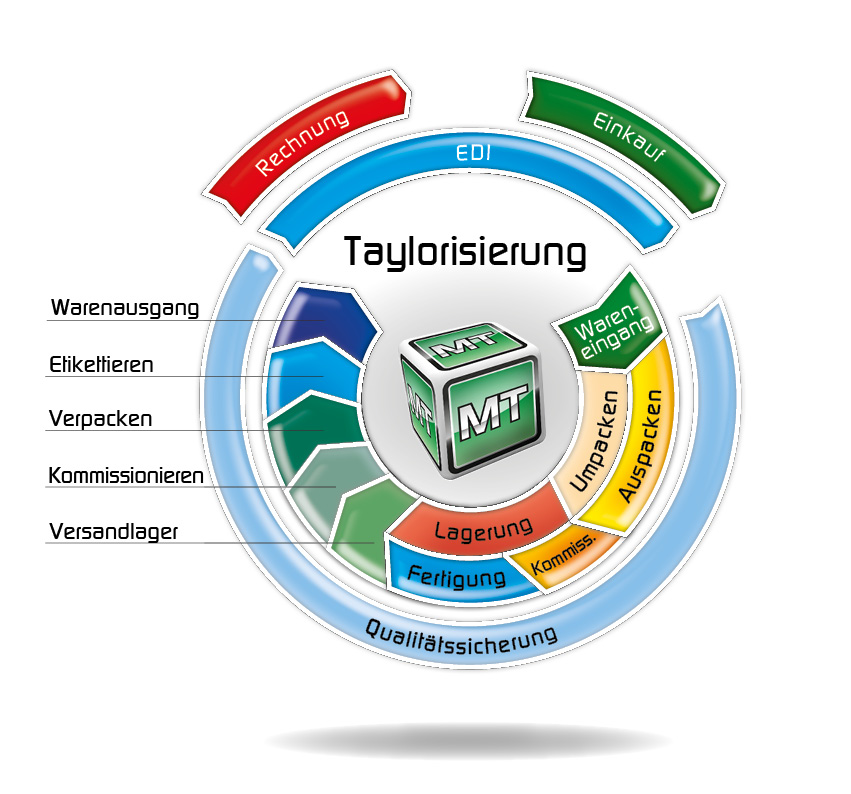

All operational logistics processes are mapped in one application.

Seamlessly integrable sub-system for intralogistics processes

mobiTOUCH maps a large part of the operational intralogistics and production-related process steps along the material flow in one application, brings transparency to the processes and is a tool for their more efficient design.

With targeted use of resources – such as personnel and equipment – and through automatic and time-synchronous booking of material movements, we achieve, together with our customers, a reduction in throughput time, an increase in inventory security and a significant reduction in search times and empty runs.

Information permanently available in real time:

- Repacking for production and shipping

- Unpacking in goods receipt

- Picking for production and shipping

- Returns

- Quality assurance inspections

- Returns due to quality defects

Material flow control is carried out by generating and confirming transfer orders with integrated inventory management.

Integrable sub-system or standalone system

As a sub-system, mobiTOUCH can be integrated into a higher-level system. Interfaces exist to common ERP systems such as SAP, Infor or PSIPENTA. Connection to production control systems (such as MPDV) for direct clocking from and in production is also possible.

mobiTOUCH is also used as a standalone system by finishers and external service providers to regulate and control, for example, cleaning processes, pre-assembly, processes in incoming goods (unpacking, repacking, packing) or shipping activities.

Modularity

The modularity of mobiTOUCH enables the individual assembly of

paperless intralogistics:

- From goods receipt

- Unpacking, separating, labelling and checking

- From warehouse management

- Storage, retrieval, ABC analyses

- and production supply, disposal and monitoring.

- Using Kanban and multi-stage waterfall methods for replenishment control

- Up to and including shipping

- Packing, picking, labelling, loading and shipping.

Targets

Perfect intralogistics

- Reduce the average dwell time of raw materials and shipped goods

- Increase inventory security

- Reduce search times and empty runs

- Shorten routes through a reservation system

- Pick directly from goods receipt to dispatch or production

- Also improve supplier resources and reduce downtime through loading window control

- Map all operational process steps in one intuitive application

Philosophy of the intralogistics solution mobiTOUCH

Agile production in interaction with agile software

- Define material flow as an event-driven process

- Select actual information conveniently

- Flexibly adapt storage location structure and topology

- Configure freely defined workflows yourself

- Display work progress in a structured manner

- Access resilient context information quickly

- Make material flows visible and adjustable

- Determine key figures flexibly

- Develop solutions together with the customer

Documents

- Materialfluss-Steuerung beim Logistik-Dienstleister M.E.S.

- Agile Produktion schafft Mehrwerte bei Takata

- Materialfluss regeln und steuern bei Arendt Logistik

- Transport-Auftragssteuerung und Workflow mobiTOUCH

- Schnelle Abwicklung von Aufträgen bei Arendt Logistik

- Effizienter Warenfluss bei Arendt Logistik